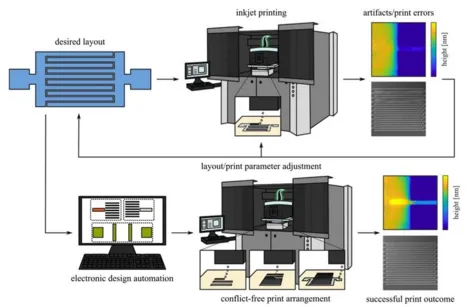

Inkjet-printed electronics is of great interest for low-cost, large-area fabrication thanks to fast and scalable processes with low material consumption. However, notable resources are currently required for fine-tuning layout designs and process parameters to prevent unintended fabrication artifacts. We propose the use of electronic design automation to mitigate such artifacts by segmenting input layouts and arranging the resulting objects in separate conflict-free layers. We apply mixed-integer-linear programming to formally model the problem and minimize the total number of layers with respect to avoiding potential printing problems. We demonstrate a more consistent fabrication outcome and significantly increased yields for optimized fabrication batches compared to non-optimized ones. The final processing of the layouts requires no human intervention and can readily be transferred to a variety of ink-substrate systems.